Despite the fact that I have a love/hate (they like digging in my blossom beds, as well as I despise them for doing it) relationship with the neighborhood squirrel population I couldn’t resist this nice-looking squirrel feeder.

This is an additional job that enabled me to take advantage of my scrap timber collection. I had a number of brief items of PTL decking boards. I joined the sides and ran them with the planer and also they looked pretty good.

You’ll require to utilize the appropriate dimension opening for your jar. I made mine fit genuine tight so while the squirrels are in the box they won’t press it out.

I was going to make use of biscuits to sign up with the feeder, however lining up the variety of small pieces appeared as well significant a job so I used Pocket Hole Joinery. I utilized among those $10 common jigs and had a hell of a time getting great outcomes. Since then I have obtained the Kreg Rocket Jig and also the difference in simplicity of use and also high quality of the hole are outstanding.

A word of care: Make certain you have a drill little adequate to go inside the “box” if you decide to use pocket-holes for your feeder. No other way can I obtain a normal drill in there to sign up with the “roofing system” without one. I used a right-angle drill accessory on mine.

Below’s an image of the finished task. Whoops! Incorrect feeder.

Here’s my feeder sans consumer. The only visible screws get on the back piece connecting it to the 3 sides. Considering that I cut 2 key-hole ports in the back to hang my feeder on my fencing post they do not reveal.

I offered the feeder 2 coats of Sherwin Williams Cuprinol Cedar Stain once setting up was completed.

I made 2 feeders while I went to it, as well as offered one to a buddy who lives in the nation. She has GREAT DEALS OF customers, lots of with wings!

I didn’t develop these plans. They were prepared by my friend Sandy in VT. And also below’s a shot of his feeder and a suggestion from him:

“I made the hole for the jar SIMPLY huge sufficient to accept the steel cover rim (a part with the screw threads) of the container as well as made use of silicon caulk to keep it in place, then the jar screws in with little or no trouble.

I reduced the slim steel cover (a get rid of the rubber seal) in half and also it functions as a ‘holdback’ so the seed does not end up on the flooring of the feeder. Another thing I’ve finished with the caulking: seals the joint where the back and also leading fulfill. I located that rainfall was coming down that joint”.

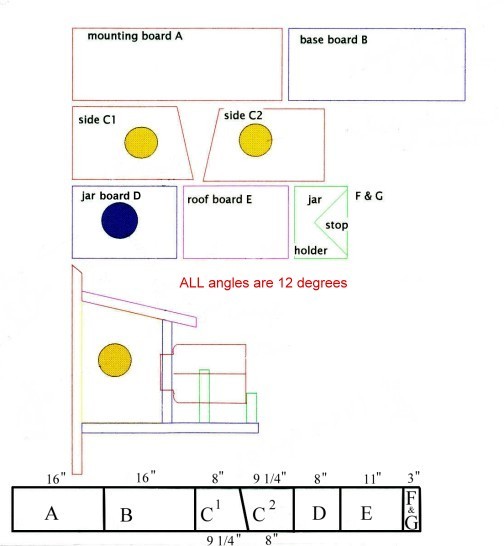

Adhere to the cutting layout below. The “stop” is optional. I cut it out and also will connect it if need be, but I choose the feeder without it.

My stock was 1 ″ X 6 ″. If I make another I would certainly utilize 1 ″ X 8 ″ and alter the 9 1/4 ″ on the “C” pieces to 11 ″.

Best of luck!

I was going to use biscuits to join the feeder, however lining up the number of tiny pieces appeared also huge a task so I utilized Pocket Opening Joinery. A word of caution: Make sure you have a drill small enough to go inside the “box” if you decide to utilize pocket-holes for your feeder. Since I cut 2 key-hole slots in the back to hang my feeder on my fencing post they don’t show.

I reduced the slim metal cover (a part with the rubber seal) in fifty percent and it acts as a ‘holdback’ so the seed doesn’t finish up on the floor of the feeder. I cut it out as well as will certainly attach it if requirement be, yet I like the feeder without it.